The alternator doesn’t stop at running the electronics. It also charges the battery, but only when the engine is running. A one-wire alternator that refuses to charge the battery should worry you because a vehicle with a flat battery won’t start. If you hire a mechanic, they will identify one or more of the following as potential culprits:

1). The Copper Post Is Dirty

Alan Murrie from this Quora post encountered this challenge. The alternator in their Honda Prelude wouldn’t charge the battery. Alan wanted to blame the battery, but it was brand new and fitted by the dealer.

When he inspected the alternator, Alan found a green crust on the threaded copper post holding the cable running to the battery. The crust insulated the cable from the alternator’s power. He solved the problem by cleaning the post.

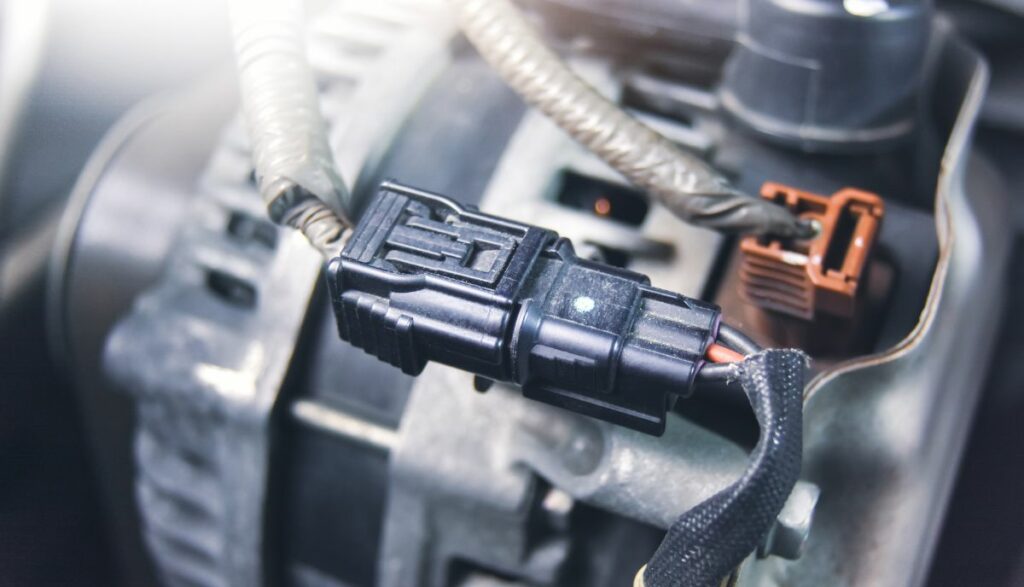

2). You Have Loose Connections

You can’t rule out loose connections as a potential culprit. Don’t forget that a vehicle’s operations expose the individual components to significant vibrations. C.E. Summers published a paper in SAE Transactions (Vol 20 Part 1), which found that variables such as unbalanced rotating parts, driving speed, and road conditions can make vibrations worse.

ACOEM USA has published an ISO vibration severity chart. Vibrations are dangerous because they can damage sensitive components.

As such, mechanics are not surprised when they find loose or disconnected connections in batteries and alternators.

3). The Battery Is Damaged

Batteries can go bad for various reasons, including extreme temperatures, loose connections, corroded terminals, electrical surges, physical damage, etc. Even if you take steps to extend the battery’s lifespan, eventually, the component will expire.

Once that happens, the battery will refuse to accept or hold a charge. Attach a multimeter’s probes to the battery’s terminals to assess the damage. Replace batteries that exceed their life expectancy.

4). The Alternator Is Defective

Like the battery, you should test the alternator for defects. Start the car and run the electronics. Does the heater work? Are the lights bright enough, or do they dim and flicker? The experts at Road-And-Track have also recommended disconnecting the battery to see whether the vehicle keeps running.

5). You’ve Blown A Fusible Link

Wiring harnesses in many vehicles have fusible links that defend against catastrophic electrical failure. A continuity check will identify this problem.

How Does One Wire Alternator Work?

What makes a one-wire alternator special? How does it differ from a three-wire alternator? How does it work? This is everything you should know:

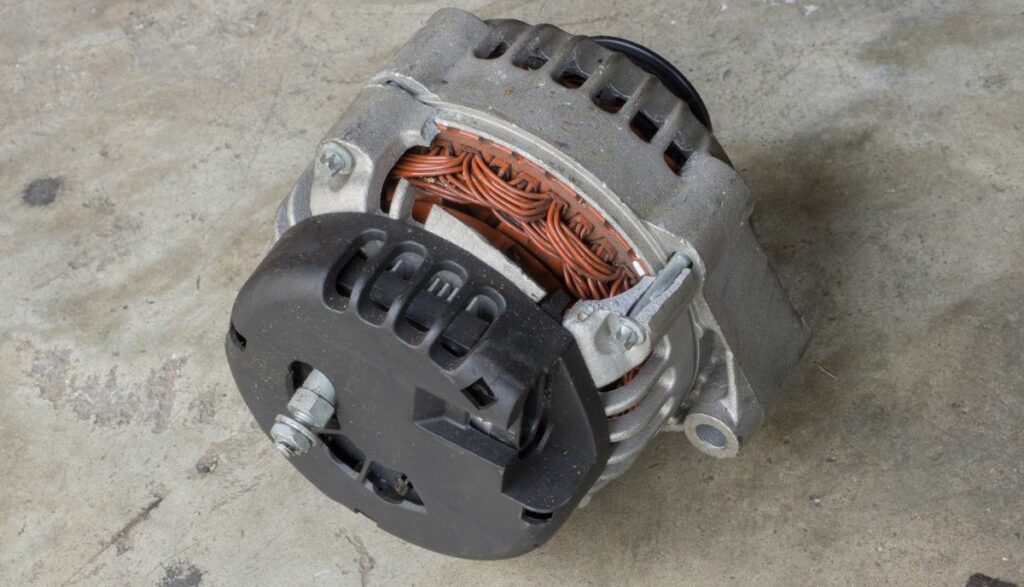

1). Understanding Traditional Alternators

An alternator turns mechanical energy into electrical energy that charges the battery and runs the vehicle’s electronics. It has a main output wire and a ground wire, not to mention a sensing battery voltage line.

Crucial to the alternator’s work is the voltage regulator, which produces a magnetic field that induces a current in the stator windings.

2). Understanding One-Wire Alternators

As the name suggests, a single wire runs between the alternator, battery, and the electrical system. Manufacturers expect the line to juggle voltage sensing and charging functions. The inbuilt voltage regulator is critical to the one-wire alternator’s operations.

It can sense the battery’s voltage through the alternator’s single wire, eliminating the need for a separating voltage sensing wire. The alternator can self-excite, charging the battery and powering the electronics once the engine starts.

3). Origins of One-Wire Alternators

Speedway Motors credits GM with developing one-wire alternators. They made the alternator for industrial and farming applications. Many consumers flock to one-wire alternators for the following reasons:

- Installation is easy. One-wire alternators are the way to go if you wish to simplify your vehicle’s wiring.

- Because one-wire alternators have fewer wires, you can maintain a neat, clean, organized engine bay.

- The absence of complex wiring configurations makes one-wire alternators a reliable charging solution.

- You can easily retrofit older vehicles with one-wire alternators.

4). Wiring One-Wire Alternators

- One-wire alternators are beneficial because you don’t need additional wiring for a voltage regulator.

- A single line between the charging stud on the alternator and the positive terminal on the battery is sufficient.

- You can convert a vehicle with an external voltage regulator by disconnecting the original wire at the regulator because the one-wire alternator has a built-in regulator.

- However, converting to a one-wire alternator makes the indicator light useless. It won’t work. But you can install a voltmeter.

- The wire gauge is essential. It should match or exceed the alternator’s maximum output. You need 8AWG for 55 to 65A and 6AWG for 65 to 100A. You can skip to 4AWG for outputs that exceed 100 amps.

- Grounding is still a necessity. It is common practice to ground through the case to the engine block or mounting bracket, although chrome finishing and paint may get in the way.

Common Problems For A One-Wire Alternator Not Providing A Charge

Despite their simplicity, one-wire alternators are not without their limitations. The following factors are a common concern:

1). Insufficient RPM

Some alternators may refuse to charge the battery because the RPM is insufficient. You need to rev the engine to excite the voltage regulator. Otherwise, the alternator cannot do its work. If you check the manual, it will mention the minimum requirements your vehicle must meet for the alternator to charge the battery.

2). Voltage Drop

Farming applications and industrial machinery use short wires with a heavy gauge capable of withstanding loads with significant electrical requirements. Alternators with thin, long cables are problematic, especially when you pair them with heavy loads because the voltage drop will prevent the alternator from charging the battery.

3). Cooling System

Cooling is just as important as the wire gauge. Electrical and automotive applications are not 100 percent efficient. They generate a lot of heat. Fortunately, manufacturers include cooling systems that prevent overheating from causing irreversible damage.

However, the cooling capacity should match the power output. If you increase the output rating, the cooling capacity should also increase. You can add more robust cooling systems to your car to accommodate heavier loads and alternators with higher output ratings.

How To Troubleshoot A One-Wire Alternator Not Charging?

- Park your vehicle on a level surface and turn the engine off.

- Wear safety goggles and open the hood.

- Find the alternator and check the drive belt. The belt runs the alternator. Some belts are too tight. Others are loose. How much play do you detect in the belt? How much movement have you observed? Can you tighten a loose belt, or does it require replacement? It depends on the severity of the damage. Replace belts with glazed interiors and torn edges.

- Start the engine and listen closely. Do you hear strange sounds? Squeaking and grinding may point to a worn-out bearing in the alternator.

- External observations are not enough to prove definitively that your alternator has a fault. Don’t make drastic decisions without checking the voltage. You’re looking for 13.5 – 14.5 volts while the engine is running. Turn the electronics on (radio, lights, AC, etc.). Readings that don’t match the information in your manual should encourage you to replace the alternator.

- If the alternator seems fine, test the battery’s voltage.

Laypeople cannot successfully assess a one-wire alternator because it means checking the voltage at different states (for instance, at cruise RPM, with the heater fan at various speeds, and when the headlights are on). The average consumer has neither the time nor the expertise to perform a thorough analysis.

What if the problem requires you to run a jumper wire from the alternator’s charge connector to the R terminal to restore the rotor’s residual magnetism? What if you blew a fuse on the megafuse block?

Despite their simplicity, one-wire alternators are still too complicated for the layperson to troubleshoot. Hire a mechanic to discover why the device refuses to charge the battery.