Yes, you can run a wire from the alternator to the battery. While the typical setup involves a line from the alternator to the starter and then to the battery, bypassing the starter and directly connecting the alternator to the battery is possible. However, caution is advised, and it’s essential to follow proper steps, including identifying terminals, using the correct wire size, and ensuring secure connections. This practice can offer more efficient power transmission but should be approached with an understanding of the vehicle’s electrical system.

Usually, a line runs from the alternator to the starter. Another line continues from the starter to the battery. Take a moment to inspect the wire between the starter and the battery.

The line is surprisingly thick because the power the starter pulls when the engine cranks exceeds the charging current the alternator sends to the battery. You can trust that battery cable to accommodate the alternator’s charging current.

However, that shouldn’t stop you from bypassing the starter completely and running a line from the alternator to the battery.

Although, some mechanics warn against this practice. They don’t want consumers to alter the manufacturer’s intended design unless they have an intimate understanding of their vehicle’s electrical system.

Consider the wiring diagram 2.5x_sleeper has published on this Subaru Forester forum. You will find similar diagrams in your service manual. If you don’t understand this wiring diagram, you should refrain from altering the charging system’s wiring.

How To Run Wire From Alternator To Battery?

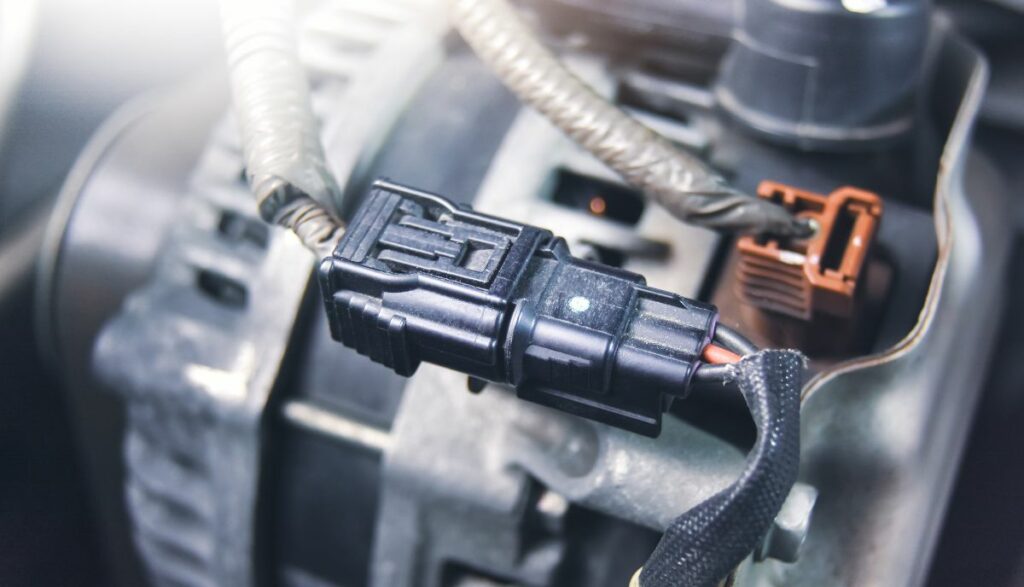

If you’ve wired alternators and batteries before, running a wire between an alternator and a battery isn’t particularly difficult:

- Disconnect the battery’s negative terminal to prevent accidents.

- Wear safety goggles, insulated gloves, and durable shoes.

- Wait for the engine to cool down before opening the hood and tampering with the alternator.

- Identify the three main terminals on the alternator (B for ‘Battery,’ S for ‘Sense,’ and L for ‘Indicator.’

- Run a wire from the B terminal to the positive terminal on the battery. Use a wrench to secure the connections.

- Run a wire between the alternator’s voltage-sensing terminal and the battery’s voltage-sensing point. This assumes your vehicle’s alternator has a separate voltage-sensing terminal.

- Run a wire from the L terminal to the dashboard’s indicator light. This allows the dashboard’s warning lights to illuminate in response to specific operations from the alternator.

- Inspect your work. Are the connections tight? Do you see loose strands? Is the insulation frayed? Don’t use electrical tape to fix damaged wiring. Replace broken and worn-out cabling.

- Connect the battery’s negative terminal to restore power before testing the charging system. What does the multimeter say? Does the alternator’s charging voltage match the readings you expect? What about the battery terminals? You’re looking for 13.8 – 14.4 volts when the engine is running.

If you’re new to this process, try to keep the following in mind:

- You can bypass the old wiring directly without altering the old wire or even removing it. Some people terminate the old wiring because it gets in the way. But you can leave it alone.

- The gauge of the bypass wire should match or exceed the gauge of the old wire.

- If the bypass wire’s gauge changes, you should consider replacing the fuse.

- Inspect the alternator belt. The alternator is useless without a healthy serpentine belt with the correct tension.

- Inspect the alternator and the battery for signs of damage. The factors that compelled you to install a bypass wire may originate from a defective battery or alternator.

What Size Wire To Run From the Alternator To the Battery?

The wire size is important because it influences the alternator and battery’s functions. The following are your biggest concerns:

- Voltage Drop

A high voltage drop limits the volume of current flowing through a conductor, which, in turn, lowers the efficiency of a charging system’s power transmission.

- Overheating

Overheating is common in undersized wires. In fact, it is the layperson’s most significant fear because undersized wires that overheat can melt, starting fires.

- Electrical Failure

Naturally, wires that melt because of excess heat will disrupt the vehicle’s electrical functions. Don’t be surprised if the alternator and the battery suffer irreversible damage.

With that in mind, what is the correct size for a wire running between the alternator and the battery? While the answer to this question tends to vary depending on the vehicle’s electrical requirements, mechanics typically target a minimum of 8AWG.

8AWG can accommodate 0-60 amps. You need 6AWG for 60 to 100 amps, 4AWG for 100 to 150 amps, and 2AWG for 190 to 250 amps. 1/0AWG will tolerate 250 to 300 amps.

Many drivers base their selection on the amps the wires will carry. However, the length is just as important. Speedway Motors has published a table showing the recommended wire gauges for alternator/battery connections.

You can see that the gauge increases with the length and amperage. Therefore, you should measure the distance between the alternator and the battery before making a decision. Use a thicker gauge to connect these components if the distance is considerable, even though a thinner gauge is sufficient for the amps you expect the wire to carry.

Longer wires have more resistance, which translates into a higher voltage drop and more heat. This is why some mechanics recommend 2/0, 3/0, and 4/0AWG cabling for 250 to 300A loads where the distance exceeds five feet.

Are There Any Risks Or Precautions When Running A Wire From The Alternator To The Battery?

- You may ruin the battery in a car where the alternator is externally regulated by running a cable from the alternator directly to the battery.

- The wire size is vital. The gauge should exceed the maximum current draw of the components it will accommodate. Otherwise, the wires will melt.

- Make sure the fuse is smaller than the wire’s current carrying capacity. Some people forego the fuse if the wire exceeds the maximum current of the load.

Are There Specific Vehicle Types Where Running A Wire From The Alternator To The Battery is Beneficial?

Laypeople have no interest in running a wire directly from the alternator to the battery. DIY experts and mechanics typically take an interest in this practice for the following reasons:

- A bypass wire between the alternator and the battery allows the alternator to generate more power.

- If you’re replacing an alternator, a direct wire between the alternator and the battery is more convenient than a conventional harness connecting both components to the starter.

- Some mechanics solve problems with the wiring harness by replacing the wiring harness even though a bypass wire between the alternator and the battery is the cheaper option.

- Isaiah Esau, from this Reddit post, bought two new alternators before realizing that his 2005 G6’s charging issue originated from the contacts on the wire between the alternator and the starter. He fixed the problem by running a wire from the alternator directly to the battery.

What Impact Does Running A Direct Wire From The Alternator To The Battery Have On The Charging System?

Running a wire from the alternator directly to the battery is appealing because it minimizes the wire length. This is good because long cables are prone to overloading, overheating, and significant voltage drops because of their high resistance.

Therefore, reducing the wire length by going directly to the battery is highly beneficial because it encourages more efficient power transmission. You can remove several feet from the wire length by taking a straightforward route.

Some manufacturers go through the starter because it benefits their vehicle’s configuration. However, others are merely working with the cards they are dealt. The engines they receive from their parent factory are prewired.

The alternator wire is already linked to the starter. Therefore, running a second line between the battery and the starter is the simplest solution. In other words, don’t assume that the vehicle’s factory configuration is necessarily the best. If a mechanic gives you the green light to run a wire from the alternator to the battery after analyzing the charging system, don’t hesitate.

Are There Potential Issues Or Drawbacks Of Running A Wire Directly From The Alternator To The Battery?

Your biggest concern is inadvertently cooking the battery and wreaking the electrical system because the alternator is externally regulated.