Ensure alternator belt tension is tight enough to prevent slippage under load but not excessively stressing the belt or bearings. Use a 1/4″ rule or a belt tensioner for accurate reference

Do you hear squealing from under the hood when you turn the air conditioner on? Is the ‘Check Engine’ light illuminated? Common sense will tell you to inspect the belt for cracks and breaks. But what if the belt is intact, and yet the symptoms above have persisted?

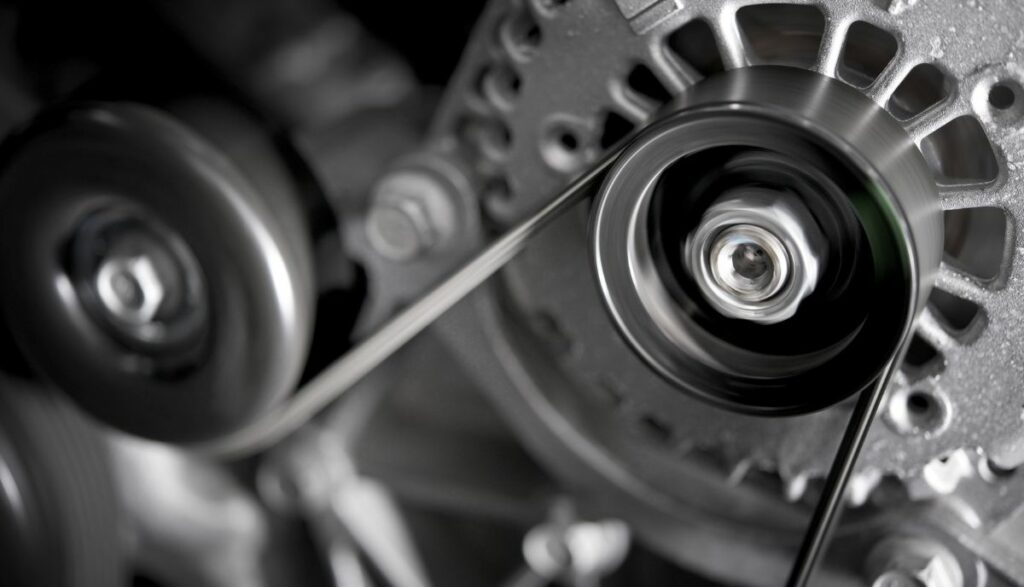

You can’t rule out the possibility that your belt is too tight or loose. Modern vehicles have a serpentine belt that snakes through multiple pulleys to run the water pump, power steering pump, AC compressor, and alternator.

The serpentine belt is less likely to come loose because it runs around numerous pulleys, especially in comparison to a conventional V-belt. However, to be on the safe side, manufacturers include an idler pulley that keeps the belt tight.

It has an internal spring that adjusts to compensate for the belt’s tautness (or lack thereof). The belt will slip once the idler pulley fails, producing squealing sounds when you exert heavy loads. This speaks volumes about the importance of an alternator belt’s tautness.

Keep in mind that a serpentine belt uses friction to move the pulleys. For that reason, manufacturers recommend a suitable tightness in the manual. For example a 1988 Nissan Pulsar manual recommends an 8mm deflection.

But if you don’t have a manual, how-a-car-works recommends half an inch of play (13mm). In other words, if you hold the belt between your thumb and forefinger, it should only move by half an inch.

A slack belt’s movement will exceed 13mm. The belt is too tight if the movement is less than 13mm.

Are There Specific Guidelines for Adjusting Alternator Belt Tension?

Not really. Alternator belts are tricky because the tightness required will vary depending on factors like the vehicle type, the belt type, and the number of accessories the belt runs. That said, most cars use the same procedure for adjusting the alternator belt tension:

- Wear protective gear.

- Turn the key in the ignition to the off position to shut the engine down.

- Use a ruler to measure the belt tension. Does it match the recommended tightness? If it doesn’t, you can proceed.

- Identify the tensioner and loosen its nut without completely removing it.

- Use a screwdriver to adjust the belt until it achieves the correct tension.

- Tighten the tensioner nut.

- Measure the belt tension again. If the tension is still wrong, repeat the steps above to adjust the belt.

The manual will let you know if your vehicle has a unique set of alternator belt tension adjustment procedures.

What Are The Consequences Of An Overly Tight Alternator Belt?

Have you ever wondered why an overly tight alternator belt concerns mechanics? The phenomenon attracts the following consequences:

- An overly tight belt will increase the strain on the bearings, causing them to fail prematurely.

- The increased strain may harm the alternator.

- You may hear strange noises, such as humming and squealing.

- The belt will wear out at a faster pace.

- The friction will increase, producing more heat. The belt and pulleys will suffer as a result.

Can Too Loose Alternator Belts Cause Issues?

Every belt becomes loose over time because of the strain it tolerates. Some belts eventually crack. Cracks can expand until the belt breaks. A loose belt will slip.

The engine will overheat because a slipping serpentine belt prevents the water pump from working. A dormant water pump prevents the coolant from flowing. Without flowing coolant, the engine’s temperature will spike.

The battery will go flat because the alternator has stopped working. Usually, the alternator charges the battery when the engine is running. The alternator belt runs the alternator.

If you have a single serpentine belt that runs multiple accessories, their performance will deteriorate.

How To Properly Tension An Alternator Belt Without Causing Harm?

Is your alternator belt too tight or too loose? You have more options at your disposal than you realize:

Using The Alternator

- Disconnect the battery.

- Find the alternator and loosen the bolts connecting the component to its bracket. This allows you to alter the alternator’s angle. Make sure the bolts are loose enough for the alternator to move within the bracket.

- Get a piece of wood and place it between the engine and the alternator.

- Pull the piece of wood back to slide the alternator in the bracket loop. This will increase the belt tension.

- Tighten the alternator bolts. Do this without releasing the wood. You should only remove the wood after tightening the bolts.

- Measure the belt tension.

- Connect the battery.

Getting A New Belt

- Some belts are too old and worn out, and adjustments won’t help. Replacing them is the only viable option.

- Find the alternator and loosen the tensioner pulley. This reduces the belt’s tension, allowing it to slide off the pulley.

- If you don’t have a manual, take a picture of the serpentine belt beforehand. This will show you how the belt usually snakes through the pulleys. Otherwise, you may forget.

- Find and install a replacement belt. The new belt should match the old belt’s length and width, although slight differences will emerge because the old belt is worn out and stretched.

- Make sure the new belt snakes through every pulley in the order specified by the manual.

- Increase the belt tension to match the manual’s recommendation.

Getting A New Tensioner Pulley

- Sometimes, a belt cannot attain the correct tension because the tensioner pulley is bad. This compels you to replace the tensioner pulley.

- Find the tensioner pulley and use the breaker bar to reduce the belt tension.

- Remove the belt.

- Usually, a single bolt holds the tensioner. Remove it using a socket wrench.

- Remove the old tensioner pulley and insert a new pulley. Ensure the pulley’s bolt is tight and the locking pin is in the correct place.

- Install the belt after inspecting it. Do you see cracks and tears? You may require a new belt.

Are There Tools Or Methods For Checking Alternator Belt Tension?

- A ruler is the only tool you require.

- Start by shutting the engine down and removing the keys from the ignition.

- The ruler will show you the furthest distance between two pulleys.

- It will also show you the midway point.

- Hold that midway point between your thumb and forefinger.

- Move the belt back and forth. You should observe half an inch of play.

- Some people use the ruler to see how far the belt depresses when they press on it.

- Inspect the belt for cracks if the tightness seems fine but you’ve noticed concerning symptoms. Some belts require a closer and more careful inspection to locate the micro-cracks.

- Are the edges polished? The belt is probably rubbing against the pulley’s lip. This points to a loose belt that requires tightening.

- Frayed edges point to misalignment.

- The grooves can become glazed because of a loose belt.