The alternator belt should generally be changed every 60,000 to 100,000 miles for serpentine belts. Factors such as age, quality, tensioner condition, maintenance, and temperature can influence the frequency of changes.

Automotive belts have changed dramatically over the decades. Initially, engineers had to make do with cotton and hemp rope. Plant Engineering traces vulcanized rubber V-belts to 1917. The material is strong, but it is far from indestructible.

Keep in mind that automotive belts use friction to generate power by turning the pulleys and running everything from the alternator and water pump to the power steering pump and AC. That friction makes heat. Alternator belts in an active engine should feel warm, possibly even hot to the touch.

You can make things worse by overstretching the belt (whenever you add a belt that doesn’t fit the pulley) and producing dangerously high temperatures through the resulting slippage. If freezing weather is common in your region, don’t be surprised if the belt suffers.

Low temperatures make the belt stiff. According to Uchanics, the absence of sufficient flexibility creates micro-cracks. In both cases (high and low temperatures), the belt will either break or the wear and tear will accelerate.

You shouldn’t drive a car with a broken belt. Some people wait for the belt to fail before buying a replacement. But that approach is dangerous. What if the belt fails while you’re driving through treacherous, isolated terrain in the middle of the night?

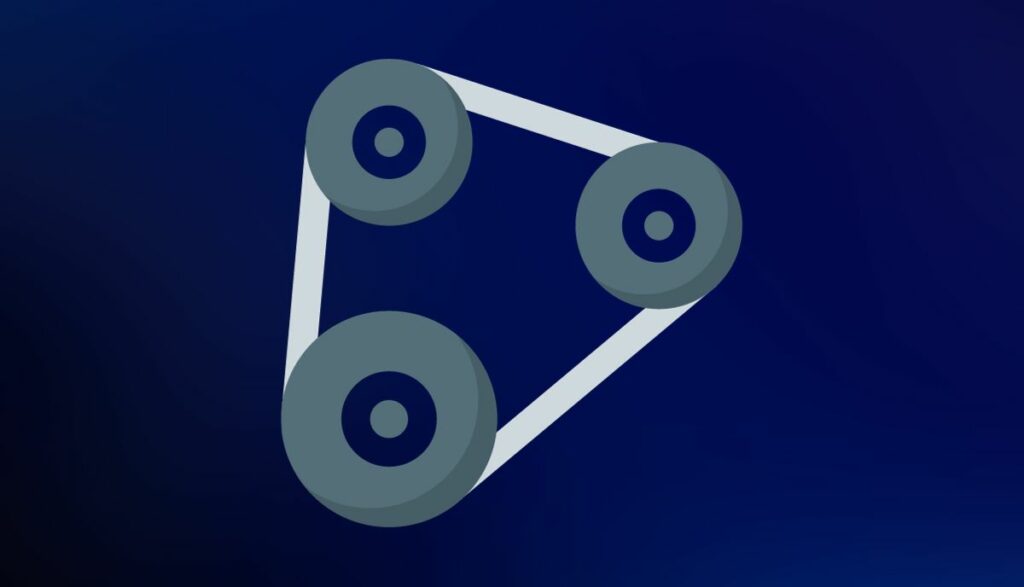

You’re better off buying a replacement as soon as you notice signs of wear and tear. This can take 60,000 to 100,000 miles for serpentine belts. If you’ve never seen one, check out this picture.

As you can see, a single belt runs through the water pump, power steering pump, alternator, and A/C compressor’s pulleys.

Serpentine belts are thicker, wider, and more efficient. But if they fail, all the connected components suffer. This is where conventional V-belts shine. You will find three or more under the hood.

Each major component gets a belt. You don’t need to replace them all if they seem fine. Stick to the alternator’s belt. Depending on your driving habits, it can fail within 40,000 miles or more.

What Factors Influence The Frequency Of Alternator Belt Changes?

The frequency with which you change an alternator belt depends on how rapidly that belt wears out. The following factors influence the rate of wear and tear:

1). Age

Belts wear out naturally as they age. This is true for most automotive components. It is largely unavoidable. However, that still gives you 60,000 to 100,000 miles of driving before the belt fails from old age.

How come some belts fail before they reach that range? Many consumers try to save money by purchasing second-hand belts, which you can get for a fraction of the cost of a new belt. This is a mistake because second-hand belts have a significantly lower lifespan.

Because you don’t know where they came from and how long they were in use before you came along, you can’t predict their longevity.

2). Quality

Buying a brand new belt (instead of a second-hand item) won’t help if the belt is poor quality. Again, many consumers try to save money by prioritizing low-quality belts from companies with questionable reputations.

They don’t realize that low-quality belts are made using substandard products that can’t stand the test of time. Even though low-quality belts are cheaper, they will cost more in the long run because they require frequent replacement.

3). Tensioner

A. Galip Ulsoy from the University of Michigan (along with N.C. Perkins and Randal Beikmann from The MathWorks, Inc.) has a paper in the Journal of Mechanical Design in which he explores the role of spring-loaded tensioners in causing belt slippage and vibrations in serpentine belt drive systems.

An alternator belt cannot perform its task unless it maintains the correct tension. A serpentine belt stands out in this field because it snakes through so many pulleys. As such, it is less likely to become loose.

Nonetheless, it still requires a tensioner to prevent slippage. That tensioner can fail, leading to slippage, which, in turn, damages the belt, forcing you to secure a replacement more frequently than you would like.

Pulley misalignment is just as problematic because it strains the belt, accelerating the rate of wear and tear.

4). Maintenance

Insufficient or irregular maintenance can lead to the tensioner and pulley problems mentioned above. The bearings can cause slippage and overheating when they fail. Additionally, you can’t rule out fluid leaks. Coolant and oil will damage the rubber material.

An alternator belt can swell because of oil and grease. Swollen belts won’t fit in the pulley’s grooves.

5). Temperature

High temperatures usually originate from inside the car. For instance, the engine can overheat due to insufficient coolant. On the other hand, low temperatures typically emanate from outside. For example, freezing temperatures in the winter can make the belt brittle and more likely to crack, especially in cars you rarely drive.

Are There Signs Indicating When An Alternator Belt Should Be Replaced?

Yes, there are. Alternator belts are not subtle. They will manifest one or more of the following symptoms, alerting you to their imminent failure:

- Expect squealing and whining noises when you start the car. These sounds may grow when you run the AC or turn the steering wheel because the load on the worn-out belt has increased.

- The battery will deplete without warning because the alternator has stopped working or is producing insufficient power. Don’t forget that a car’s alternator charges the battery. It also runs the electronics. Those electronics will drain the battery if the alternator stops working.

- The lights will dim and flicker because of the vehicle’s faltering power supply.

- The engine will stall.

- You will notice a burning smell because excess friction is producing too much heat, hence the scent of burning rubber.

Are There Preventative Measures To Exceed Alternator Belt Lifespan?

- Buy high-quality belts from reputable retailers.

- High-quality belts will fail if you install them on worn-out pulleys. If you’re buying new belts, inspect the pulleys and consider replacing them as well.

- Make sure the belts and pulleys are correctly aligned.

- Match the belt size to the pulley’s dimensions.

- Don’t apply lubricants to the belt during servicing. They will slip.

- Service the car as frequently as the manual demands.

- Clean the engine to prevent dust and debris from accumulating.

- Use a block heater during the winter.

What Happens If Alternator Belts Are Not Replaced On Time?

They will wear out until they break. The consequences will depend on the number of belts in your car. Some vehicles use multiple belts for each component. In other words, a dead alternator belt will only affect the alternator.

That is still a problem because the alternator runs the electronics and charges the battery. Once it fails, the battery will become the primary electrical source in your vehicle. You can still drive the car, but you risk depleting the battery. If you shut the car down after draining the battery, the engine won’t start again until you charge the battery.

However, that is technically the best-case scenario because the car can still start and run if you connect an external charger. A single belt that runs the alternator, power steering pump, AC compressor, and water pump will prevent you from driving the vehicle once it fails.

After all, the water pump keeps the engine cool. Driving a car with an inactive water pump can lead to engine overheating. You’re better off asking a mechanic to come to you. Otherwise, driving to the repair shop may damage the engine irreversibly.