You can pair electrical tape with most electrical applications. But what about car battery terminals? The guide below will tell you whether or not car battery terminals and electrical tape are compatible with one another.

Can You Put Electrical Tape On A Car Battery Terminal?

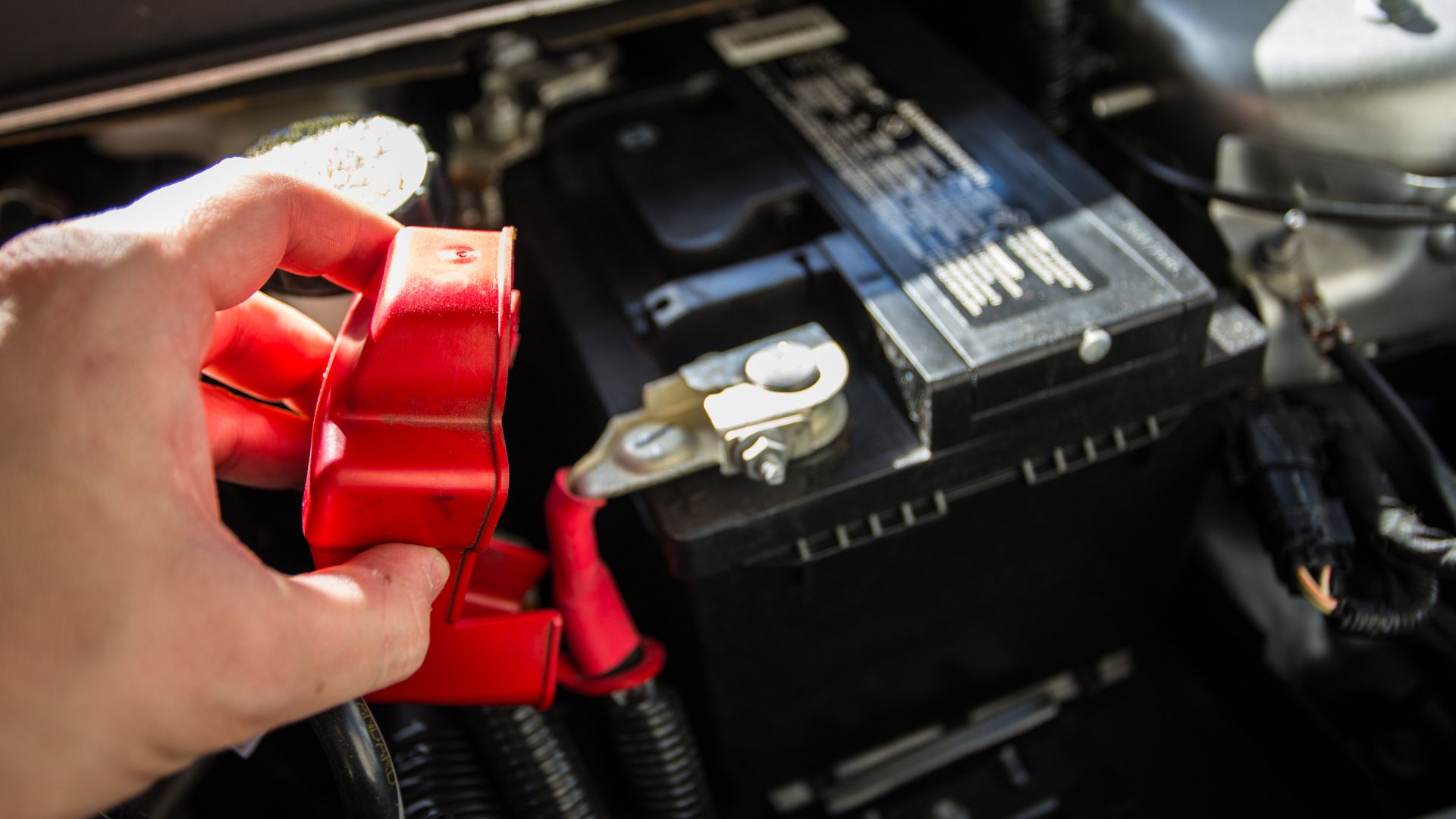

You can put electrical tape on a car battery terminal. Covering them with tape prevents interactions with metal objects. If these interactions occur, a fire will start. Fires are not your only concern. Short circuits can also occur.

Some people prefer to keep electrical tape away from their cars because they think it harms the paint.

But that is not true. At worst, it will leave a sticky residue. Electrical tape can only harm your paint if you leave it on the vehicle’s body for too long. You may cause some minor damage by ripping the tape off quickly.

From what Battery Solutions have seen, most batteries don’t need tape. But you can apply it for the sake of caution.

Is Taping Car Battery Terminals Safe?

Electrical tape is no different from other types of tape. Its efficacy depends on the way you use it. This is what you should know:

1). Use Proper Color Electrical Tape

You can find electrical tape in numerous colors, including green, yellow, and brown. However, these colors do not serve an aesthetic purpose. Instead, they reveal the tape’s attributes. This shows you the applications you can pair with the tape.

You should select the color carefully because it influences the voltage level the tape can withstand. The wrong tape introduces electrocution hazards.

2). Add Multiple Layer Of Insulation

People use electrical tape because it adds a layer of insulation. It can prevent live wires from creating a short circuit by coming into contact with one another. This is why it appears prominently in electrical projects.

But short circuits are not your only concern. You can apply electrical tape to protect the terminals from harsh environmental factors. This is part of the reason why technicians cover battery terminals with electrical tape before putting them in storage.

3). Don’t Use Electrical Tape As Permanent Solution.

Manufacturers use rubber-based compounds to make this product. This allows the tape to conform to the shape of the battery terminal. But it will also break down over time, losing its grip and flexibility.

The duration depends on the application and environment. Some layers of electrical tape will only last a few weeks. Others will survive for months, possibly even years. Ultimately, you can’t trust electrical tape to play its role in the long term.

You should wrap the terminals knowing the tape will become brittle and tear or fall away once its strength fades. This should encourage you to look for a permanent solution to whatever problem made the electrical tape necessary.

4). Electrical Tape Is not Waterproof

If you’re trying to protect the terminals from water, you should know that electrical tape is not waterproof. People wrap the product around water pipes and hoses because it has a certain amount of water resistance. It can tolerate moisture for a while. But it won’t withstand large volumes of water.

Additionally, damp conditions will make the tape less effective. Don’t be surprised if it stops being sticky. RS Online encourages consumers that prefer waterproof tape to use PTFE tapes. They repel water.

5). Electrical Tape Is Not Fireproof

Electrical tape is not fireproof. But you can apply it to battery terminals in hot conditions because the item is heat resistant. From what Engineer Fix has seen, the temperatures shouldn’t exceed 80 degrees C.

6). Prevents Exterior Environments

If various circumstances have forced you to keep the battery outside, you can still apply electrical tape. But again, this is a temporary solution. The item will only resist weather elements such as rain and direct sunlight for a short while before it gives way.

How To Apply Electrical Tape On Car Battery Terminal Safely?

- Select electrical tape whose attributes match the elements it will encounter. Make sure the tape can withstand the heat and moisture levels you expect. Manufacturers have documentation that explains the attributes of each color.

- Apply as many layers as you think you need. Don’t stop at one layer.

- Pull the tape as you apply it. Stretch it to enhance the tape’s grip. Otherwise, it will fall off sooner than you expected.

- Don’t be afraid to use locking nuts and shrink wrap if the electrical tape keeps falling off.

- Don’t add insulating material to electrical tape to enhance its insulation.

- Don’t expose the tape to external conditions. The item is not as weather-resistant as people think. Use stronger sealants and adhesives that offer sufficient waterproofing.

What Kind of Electrical Tape Should I Use?

It depends on the obstacles you expect to encounter. You have various materials to choose from, for instance:

- PVC tape is one of the most common types of electrical tape on the market. It does a little bit of everything, which is why you are more likely to see it on battery terminals. But you shouldn’t expose it to high temperatures. Electrical tape can catch fire if conditions get hot enough. PVC can withstand corrosion, abrasion, and extreme weather conditions.

- PTFE tape offers impressive chemical resistance. If you can keep temperatures below 300 degrees C, PTFE tape can withstand many harsh solvents. Additionally, this material cannot conduct electricity. Therefore, you can expose it to mediums with an electrical current.

- Cloth electrical tape has poor dielectric properties. It shouldn’t be your first choice if you need a strong insulator. But the tape offers superior strength and flexibility.

- Rubber tape is strong enough to survive construction sites, manufacturing plants, and other rugged settings.

- Mastic tape is known for its considerable moisture resistance and flexibility.

- Vinyl tape does everything. The material delivers decent moisture, chemical, temperature, and abrasion resistance.

As you can see, you have plenty of choices. The threats you want to combat will shape your selection.

When Should I Not Use Electrical Tape?

Don’t use electrical tape on the engine. The heat will compromise the tape, loosening its grip. It will come off fairly quickly. But the battery terminals are far from the engine. The heat is not a problem in this particular situation.

People prefer electrical tape where battery terminals are concerned because it won’t damage the terminals. More importantly, they can remove it with relative ease to check on the terminals.

Related post: